This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Messages - the-chauffeur

Pages: 1 ... 6 7 [8] 9 10 ... 13

106

« on: August 21, 2011, 05:24:13 PM »

Yeah - that's what I thought. Sadly, the engine has other ideas.

There's a leak between the crankcases in the sprocket area - the part of the cases that sit between the sprocket and gearbox. Yes, it's definitely there and not the seal behind the sprocket; I cleaned everything with thinners and then put talc on it to see if I could trace the problem (which was oil doing more than just dripping off the bottom of the engine).

Christ. Either I'm cursed or this f*cking engine is. Still, it's not a mechanical problem, so it's not an expensive fix; just time consuming. Again.

<sigh - again - sigh>

107

« on: August 19, 2011, 07:38:24 PM »

K2 - entirely agree; good engineers know their limits, better ones can also plan their workloads. Shame about the few that seem to let their enthusiasm (?) run away with them.

Pete - yeah - Mark is at R&G. I'd always thought he had a pretty decent level of attention to detail - case in point, he's rung me today to check I'm happy with the shade of silver I've chosen for the 'new' SL350 frame and whether I wanted the yoke pieces different colours (I do). And he tries to do all the bike work himself, rather than leave it to his lads. I'm sure if you tell him how important it is to hang the frame on a rack from the point at which it's powdercoated onwards, he'll be more than happy to do it.

I've heard of SEP; wasn't there an article on them in a recent copy of CMM? Fingers crossed I don't need anything much engineering-wise in the near future.

As far as the ignitions go, I'm going back to points on my CB450 from a modified (i.e. botched) Dyna unit - that's been an expensive and enormously frustrating exercise - and I'm putting Hondaman units on all of the bikes to take the load off the points and turn them into relays. At least if HM's units go bad all I need to do is unplug them. Agreed - valves on bikes like the 750 with screw adjusters are fairly simple, but not so much on the smaller SOHCs (350's) 'cos they've got eccentric adjusters. They're also a PITA . . .

108

« on: August 18, 2011, 09:25:06 PM »

Pete

Kinda depends what I want doing.

Folks I can rely on include Dale the polish in Dartford, and welding will now be going to Shaun - both in Victoria Business Park off Victoria Road. I know you've got misgivings about R&G Finishers in Crayford, but I'm sticking with Mark for blasting/powdercoating for now. Paint is from Andy at ART in Ashford; he can also do 2-pack on frames and he'll collect/deliver. And vapour blasting always goes to Dave at TSR in Sevenoaks.

Things get more tricky with engine work. Anything of a head/face milling nature would probably go to the place that makes injection moulds in the same business park as Brian. Took them 20 minutes to flatten a cylinder head for me. Rebores go to Slipstream Tuning in Sevenoaks - good, but pricey. Sadly, it's downhill from there . . . I'm getting the same runaround with camshaft/rocker work from Phil Joy (Joy Engineering) that I was experiencing with Brian, which is both frustrating and depressing (there aren't many doing what he does). Quality/product/knowledge is great; reliability is bad and getting steadily worse - and given that it's distance work, it's even more disconcerting than it would be if you knew you could pop round and take stuff back.

I try to do just about everything else myself; wheel building, wiring (electrics on the older ones I'm working on are very, very simple), and I find upholstery pretty straightforward. Not tried anywhere for chroming yet - just tried to make the best of the bits I've got. Quite fancy a go at plating at some point, but I want to get all of the bikes back together, running and oil tight before I start out on that little adventure. Having said that, I'll hold my hands up and say I'm all fingers and thumbs when it comes to setting points and valve clearances - I know I should be well beyond that by now, but I find both desperately frustrating, so I'll occasionally pay someone to do those last bits.

That's a start I guess . . .

109

« on: August 11, 2011, 10:54:05 PM »

I'm really sorry it's come to this, but I'm posting a warning to anyone considering using Engineering Solutions in Bexley.

If you're a reader of classic bike magazines, you may have seen their ads - they say they take on all sorts of engineering work. It's fair to say Brian (the proprietor) will be happy to take it on, and talk about it at great length . . . it's the doing it and returning it that's a problem. Particularly welding.

Those who've seen my other posts will know that I've spent more time waiting for bits to be worked on than I've spent working on my bikes. Out of the last six months or so, Brian has kept me waiting for nearly five for what are really very simple jobs - welding on exhausts, thread repairs, minor headwork and so on. But the most recent job has just about driven me up the wall.

Three months ago, I took a frame in to him with some ancillaries for some straightforward alterations - the lock stop had been pushed sideways and needed straightening, the shock absorber bushes needed pressing out of the swingarm, a couple of threads needed repairing, a couple of seat pans needed tack welding in a spots and the underside of a silencer needed some weld repairs. Since that time, I've gone back in every couple of weeks or so and been told that it's happening - but each time, my pile of bits hasn't moved from where it was on the last visit.

Four weeks ago I told him I had a deadline of two weeks and explained why. Somewhat unsurprisingly, that deadline came and went, but only the frame went to his welder. I was fuming this week when I went into the shop to see the pile had remained unmoved, only to be told Brian had gone on holiday for two weeks, and once again, nothing was going to happen until he'd returned. I collected what I could and took it away and have since had all of the bits done overnight by more professional people. I'm also pleased to say one of his helpers got the frame back for me, too.

This isn't the first time he's royally pissed me about - he had a set of silencers off me for at least 8 weeks and basically did nothing with them in that time. But again, he kept telling me they were being worked on . . . and on . . . and on. Eventually I had to take them off him and get someone else to do them.

Don't get me wrong - the engineering work he's done for me in the past has been good, although it has taken forever to get it done. I've tried really hard to be patient - and some would say I've been too patient - but I'd prefer to give someone a fair go before getting bent out of shape. At the same time, I don't want to come across as a ranting lunatic, but this last experience has just been a hop, skip and a jump too far for me.

If you've got all the time in the world, Engineering Solutions in Bexley may just be the place for you. But if you want stuff done and returned to you while you're still young, save yourself a load of grief and aggravation and go somewhere else.

110

« on: August 07, 2011, 10:50:16 AM »

I'll answer my own question for those who're interested with the wisdom of Hondaman:

"Boy, I know all about the hectic part!

The casting: the main reason these were closed on the bottom was to keep oil seepage up those threads to a minimum. Honda has always been concerned that their engines should be dry on the outside. If the engine is still open, you might try using a bit of JB Weld epoxy, fresh and well-mixed, after cleaning the site with acetone or lacquer thinner. This epoxy work well by gripping those pores and sealing into them, and it withstands engine heat easily. It is impervious to hot oil, once cured. It is a mainstay of the repairs I have done to both these aluminum engines and cast-iron ones, for years. But, it must be FRESH, not old, and well-mixed, and applied no more than 3mm (1.8") thick.

It's actually good that the little piece fell out now: it could have popped up into the tranny gears and locked them tight while snapping into a hard shift into 2nd gear near redline. Makes a real mess (and we won't discuss how I know about this little event...). :-D"

Bearing in mind my 350 and 450 both have open ended cylinder stud holes, I reckon it'll be fine as is. Which is something of a relief - as is the fact that it went when it did and didn't wait to spring a really nasty surprise on me . . .

111

« on: August 06, 2011, 11:28:25 PM »

Well, it's been a day of ups and downs.

We pulled the engine earlier today, flipped it and opened it up. It was fairly obvious where the sealant was missing - there was a space about an inch wide, which is very weird, but hey. We cleaned the mating faces before applying new sealant and with all that done and the halves bolted back together, we flipped the engine right way up. Everything checked out (gears and crank-wise) and we're just moving it back to the bike when . . .

. . . we noticed what looked like a small silver plug that had fallen out of the cases. On closer inspection (and some hunting with a torch) it appears to be the internal end covering of one of the cylinder studs - I can see the top of one if I look very carefully. The piece of casting is only about the size of a 20p piece and it's a couple of mm thick; there's no thread on it, but it's got a domed indent in the centre. We didn't touch the studs this time - no need. All we were doing was taking the bottom case off and putting it back on - so I can only assume the end cap had fractured when I replaced the standard studs with heavy duty ones and it been waiting for the right time to fall off . . . and that time happened to be now.

I can't see any other case damage anywhere, and it's certainly not spread or cracked anything else, but what I'm hoping someone can tell me is whether it's safe to run as it is - insofar as will the rough casting hold up to being continually splashed with engine oil? I know the cases are strong enough as they are, but I'm just a little concerned that the unfinished surface left by the missing cap might be too porous and/or should be resealed to stop it crumbling.

I'm praying that it'll be fine as it is, and that I'm just me being over cautious - I really don't want to go through an entire stripdown again.

>sigh<->again>

112

« on: August 03, 2011, 11:15:25 PM »

Oh yeah - the big one that goes round the oil path dowel. Both are there - and were new when I put the two halves together last time.

I'm struggling to remember now, but I have a feeling that when I put the bottom half on, I had some trouble with one of the bearing retainers not fitting quite right. I replaced all of the bearings with SKF's and had to have retaining grooves cut into the sides of a couple of them - and one in particular was a very tight fit. Anyways, I thought I'd got the cases squared away but hadn't, and had to reopen them - and I guess I disturbed the liquid gasket stuff.

Whatever - it's going to be hard work. Again.

>-sigh-<

113

« on: August 03, 2011, 10:40:24 PM »

Well, I thought it was cool. I was wrong. After stripping and rebuilding the top end, I got to run the bike last week. Top end was pretty much fine, and the smoke from #4 was residual oil (WD40 or similar) in the exhaust pipe. However, I couldn't help notice what seemed to be oil dripping from the front filter housing. Closer inspection revealed the housing was fine, so the next logical conclusion was that it was old oil that had leaked from the cylinder base, dried on and then liquefied when everything heated up. Sadly, that would just be too easy. Seems the base gasket leak masked a smaller, but equally significant leak - from the joint between the crankcase halves. Never seen that before, but it's there. Like the other leak, I'm putting it down to a properly functioning oil pump increasing the internal pressure, but that's little consolation. Looks like the only remedy is to pull the engine, flip it, unseal and reseal and put it back in again. At least that way I can be sure it's done right. I'm sure every step I go forward is getting me closer to having a properly sorted bike, but it sure as hell is putting me through the ringer to get there.

114

« on: August 03, 2011, 12:18:58 AM »

Mick

According to Hondaman's book, the lower advancer is from a K2. The book has a picture of three alongside eachother (K1, K2 and K4) - the giveaway with yours is the number stamped up the side - 40125-01.

HTH

115

« on: July 22, 2011, 09:18:26 PM »

Cheers guys. Bryan - thanks for the pointer on the idle speed. From what you've said, I think I may have been aiming a little too low. I'll wait for the new rubbers to arrive and then have another go at setting it up.

116

« on: July 21, 2011, 10:29:08 PM »

Thanks as always Pete.

Good point about leaks - some of the (very few) bits I haven't yet replaced during the various rebuilds are the carb-to-engine rubbers. I've done the carb-to-airbox rubbers, but not the ones forward because I guess I thought they were so thick, leaks were unlikely.

However, I'm also having more and more difficulty mounting the carbs in such a way that they sit parallel to the engine head without coming into contact with the fuel tap. Are the numbers on top of the rubbers 'sposed to face directly upwards or be offset in some way?

Whatever, I've been wondering whether the rubbers may have shrunk (or something) - they've certainly hardened quite a bit over time. Since that might have something to do with the mounting/funky idle, I've just ordered a new set from Silvers. But it's interesting to hear you have similar issues with other years.

One other thing - one of the guys at 21st Moto (local to me) has asked if they can borrow a couple of my bikes to put on display when they have an open evening in a few weeks time. I thought that was pretty cool . . .

117

« on: July 21, 2011, 07:05:42 PM »

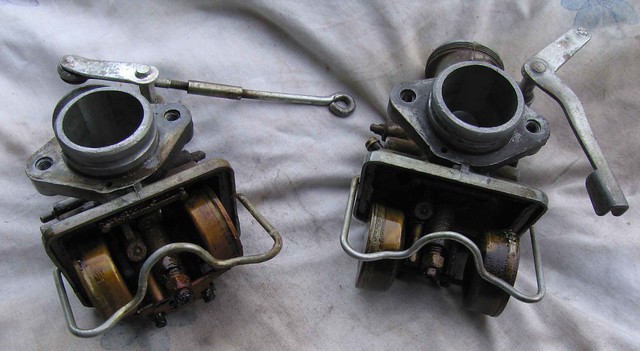

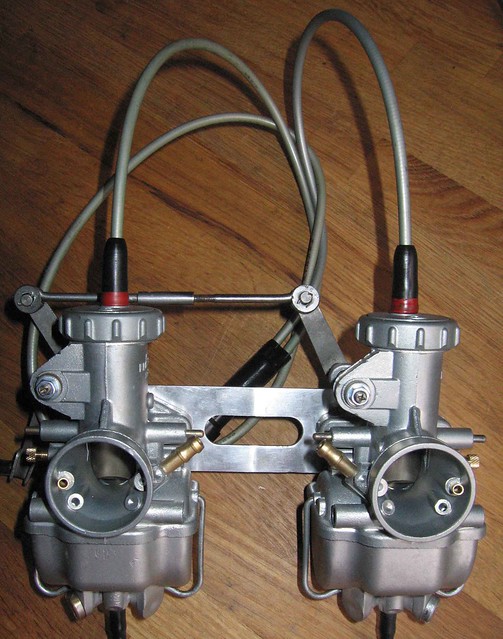

Hey gang After w-a-y too much work, rework and re-re-work, I think it's safe to say the 750 K2 is nearly finished. Hooray. I've just swapped the head for that of a K3/4 which is much smarter than the one that was on there, and it fires up and runs very well. With a list as long as your arm of new parts, vapour blasting and rebuild work, it's now lookin' pretty good. It's even quite quiet, which I'm sure has something to do with new chains and bearings throughout. Anyways, one remaining thing I've never been able to sort out is the carbs. What I mean by that is that when it's running at idle, either the engine is struggling to stay ticking over or it's racing - there's no middle ground. It's almost as though the thread on the idle screw is too coarse, because no matter where it's adjusted to, the idle's either way too low, or far too high. Off idle (i.e. under power) it's fine - and very responsive - but calm idle is proving elusive. The carbs have been entirely stripped out, vapour blasted, ultrasonically cleaned and all of the jets and other internals have been replaced with new bits. I've also synched them and made sure the all the linkages/gates (inc. choke) are matched to eachother. And yes, the cables are free and have slack in them. So they now look lovely (almost as good as a set of SL350 carbs I've just redone); shame they don't seem to be controllable. Just in case you were wondering, this is pretty much what I start with: . . . and once I've soldered up the holes in the floats (!) and overhauled them, the carbs end up looking like this: But back to the 750 carbs, I'm trying to work out whether the idle I'm stuck with is how the 750's are generally, or whether this is something particular to mine - and if it is mine, why? What do we think?

118

« on: July 20, 2011, 11:32:10 PM »

If you're planning on doing any work on the frame (delugging/powdercoating) I'd strongly suggest getting hold of a Gordon frame kit from one of the fellas on the US SOHC4 site. You chop out a section from the two supporting struts under the main spar under the tank and weld in threaded inserts that allow you to take the top off the engine whilst it's still in the frame.

For various reasons I've had to take the head off my K2 a few times in the recent past, and if I didn't have the kit fitted, what currently takes me an hour or so would have taken me days pulling the engine out and putting it back.

119

« on: June 26, 2011, 07:58:03 PM »

Thanks Pat - although I'm not quite sure what o-ring you're referring to. The only part between the cylinders and the head (other than the gasket) is a dowel - hence the original question as to whether 'they all do that, sir' or not.

120

« on: June 26, 2011, 05:14:35 PM »

I'm still in the first 1,000 miles after rebuilding the 350 K0 twin, and I can't seem to clear up what appears to be an oil seep from the RHS of the head gasket. The top end is pretty much tight, and it certainly isn't blowing, but every time I give the bike a good run out, I return to find traces of oil on the top fin or two of the cylinder block right hand side. I should add that for a short while, I had a leak from the tacho seal and earlier it suffered from sealing washers that weren't on the top of the engine. Must've been like it for a month or so (which I originally thought was caused by the head gasket) but stopped immediately when I replaced the seal/replaced the sealing washers.

My question is, are the 350's known for leaking from the head gasket, or have I just saturated it with oil from the tacho joint? I know the oil feed to the head is on the right, and I'm wondering whether that's a known weak spot. I'm guessing it could be old oil drying out from the gasket, but I'd've thought that would've dried out within twenty miles or so with a hot engine.

Or should I just wait another few hundred miles before I start worrying about the oil traces . . . ? Meanime, I'm considering trying to find a set of heavy duty engine studs - any good sources out there?

Pages: 1 ... 6 7 [8] 9 10 ... 13

|